SCPulley: Difference between revisions

No edit summary |

No edit summary |

||

| Line 37: | Line 37: | ||

[[File:SCPulley1.jpg]] | [[File:SCPulley1.jpg]] | ||

[[File:SCPulley2.jpg]] | |||

2. SC shaft details. The pilot hole in the shaft had a square wedge driven into it to prevent the standard pulley pullers | |||

from working. The SC oil fill plug is the brass plug on the LHS bottom. | |||

[[File:SCPulley3.jpg]] | |||

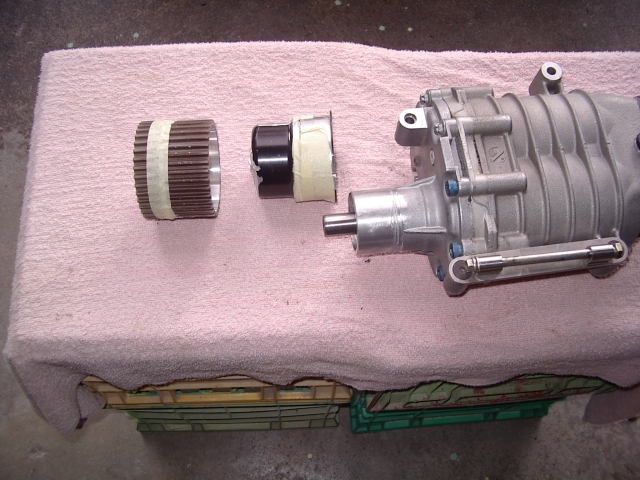

3. The new SC pulley is shown below. I had the teeth made a bit narrower as I had measured the tracking position of | |||

the belt. The gold/ black thing on the LHS is a Fenner Trantorque bushing I used to fix the pulley on the shaft. | |||

It is an expanding bushing that locks the both the pulley & shaft. 45mm od/ 20mm id. The factor of safety on the | |||

bushing toque vs. SC pulley torque is about 10. The bushing uses 1-1/2 & 1-1/4 in wrenches to tighten up & is torqued to | |||

about 300 in-lbs from memory. | |||

[[File:SCPulley4.jpg]] | |||

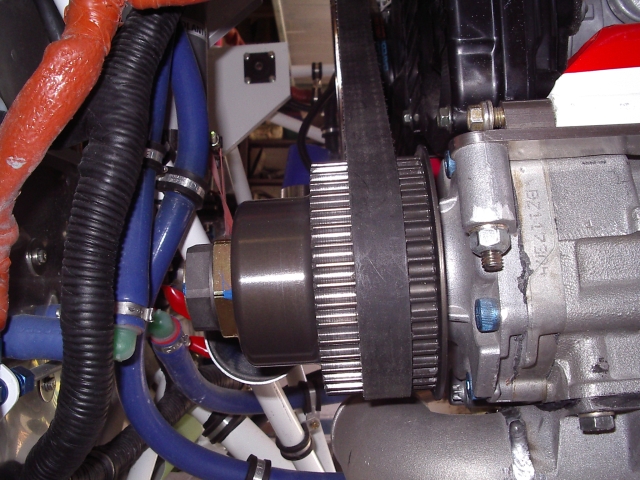

4. Pulley installed. The existing belt is reused & consequently, the SC mount bracket has to be shortened by about 0.4 | |||

in. I also replaced the SC tension rod with a proper turnbuckle arrangement so that the belt could be properly tensioned | |||

to remove most of the "belt slap" evident using Eggs SC rod. I also bout a $20 belt tension tester from McMaster- | |||

Carr so I could properly set the tension in future. | |||

[[File:SCPulley5.jpg]] | |||

Revision as of 02:57, 6 December 2009

Super Charger Pulley Replacement

John Moody

I saw your comments regarding the supercharger pulley replacement. No need to reinvent the wheel. I did all that a couple of years ago including redesigning the pulley & sourcing a fabricator.

I changed the pulley from a 36 teeth unit to 42 teeth (about 4.2 in dia) - this change reduces the drive ratio to 108/42 = 2.57 & the maximum SC speed to 14000 rpm @ 5450 engine rpm ( 2700 prop rpm) for the G3 PSRU

I assume that the SOHC H4's use the same 108 teeth drive pulley as the STi's.

Below are a series of photos I took during the removal/ replacement process:

1. The existing pulley is 2 pieces. A thick aluminium "bell" press fit onto the SC shaft with a thin "teeth ring"

pressed on to the bell. I didn't have any prior knowledge of what was there before I started cutting it off so I did it the hard way.

First step is to cut off the teeth ring - it is only about 3/32 in thick & the bell lip below is about 1/16 thick so go easy

with the dremel. See details in the second photo.

Second step is to cut-off the bell without nicking the shaft. The bell/ shaft overlap is 1 in. I used a series of parallel

cut to get down near the shaft. I then cut-off the thin part of the bell & used a cheap gear puller to pull off the bell.

I think Brian Meyette went straight to the gear puller & it worked OK.

The SC shaft is 20 mm dia (0.787in +/-)

2. SC shaft details. The pilot hole in the shaft had a square wedge driven into it to prevent the standard pulley pullers

from working. The SC oil fill plug is the brass plug on the LHS bottom.

3. The new SC pulley is shown below. I had the teeth made a bit narrower as I had measured the tracking position of

the belt. The gold/ black thing on the LHS is a Fenner Trantorque bushing I used to fix the pulley on the shaft.

It is an expanding bushing that locks the both the pulley & shaft. 45mm od/ 20mm id. The factor of safety on the

bushing toque vs. SC pulley torque is about 10. The bushing uses 1-1/2 & 1-1/4 in wrenches to tighten up & is torqued to

about 300 in-lbs from memory.

4. Pulley installed. The existing belt is reused & consequently, the SC mount bracket has to be shortened by about 0.4

in. I also replaced the SC tension rod with a proper turnbuckle arrangement so that the belt could be properly tensioned

to remove most of the "belt slap" evident using Eggs SC rod. I also bout a $20 belt tension tester from McMaster-

Carr so I could properly set the tension in future.